What good is Precision Conservation if it doesn’t help us apply conservation better and faster? We should expect that a part of Precision Conservation should simplify and automate the routine and the mundane, so the professional conservationists can engage in meaningful conservation planning.

My new favorite Precision Conservation topic is fully automated 3D machine control. This will be one of the game changers we have been looking for, if private businesses and government entities can work together.

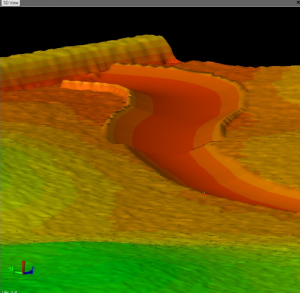

Recently, I worked with Ryan Murguia of Quantum Land Design and Tom Abell of ZieglerCat. In just a few minutes, Ryan generated a line file and we had a fully developed machine control file to build a waterway. In all, this design took about 45 minutes. I have known about machine control for a couple of years, but seeing one of my waterway designs turned into a 3D file was an absolute thrill.

According to MachineGuidance.com.au, machine control technology “not only displays the machine’s position, but it also directly controls the machine’s ground engaging tools. By controlling the machine hydraulics, the system is able to automatically move the blade/bucket towards the correct grade allowing the operator to concentrate on driving the machine. Construction accuracies can be greatly improved by using automated machine control systems.” I realize this technology is nothing new in the road construction world. It seems like every dozer or grader on a road construction site has a GPS unit on each side of its blade. However, for soil and water conservation….wow! I can’t remember the last time I was this excited about new technology.

Now imagine a technician designing a structure like a grassed waterway using LiDAR data. Once designed, he hits a button to create a 3D machine control file and emails it to the contractor. The contractor then uploads the file into his unit on a dozer or grader and builds the structure without any staking. This could all happen within the timeframe of a day. This is one of the game changers for which we have been waiting.

Machine control technology will fundamentally change how conservation structures are designed, staked, and constructed if private business and government can work together. Government technicians are already using LiDAR to design waterways. The software is already available to utilize LiDAR data and develop a grassed waterway design and machine control file in 30 minutes. Developers (companies like Trimble, Topcon, and Leica) are poised and waiting to expand the use of machine control to soil and water conservation. What’s left? Well, it is kind of like the chicken and the egg question; which comes first? Contractors want to know they can get a machine control file for a design before purchasing the technology. Technicians won’t use software that creates a machine control file if there is no demand. Fortunately, we have a few contractors and technicians crossing the road. By getting government and private business working together, machine control will grow rapidly.

And, we are just scratching the surface, so to speak, with machine control. Machine control files can be created for practices like ponds, wetlands, water & sediment control basins, water control systems, and terraces. I recently talked to a contractor who is using machine control and he said that after he completes a project, he can create a file of the final shape. In other words, he can develop a “contractor check-out” file. These are exciting times.

Thanks to Tom Abell of ZieglerCat and Ryan Murguia of Quantum Land Design. In next week’s post, I will discuss more about contractor adoption of machine control.

I’m excited about the possibilities this technology brings to the local USDA and SWCD offices. With the decreases in future staff due to budget cuts, the decision-makers need to look at better ways to get things done quicker, easier, and with less staff time. Industry is way ahead of government, but needs their backing for utilization in the field.